Electrical Insulation Materials – the Development of Electric Boards

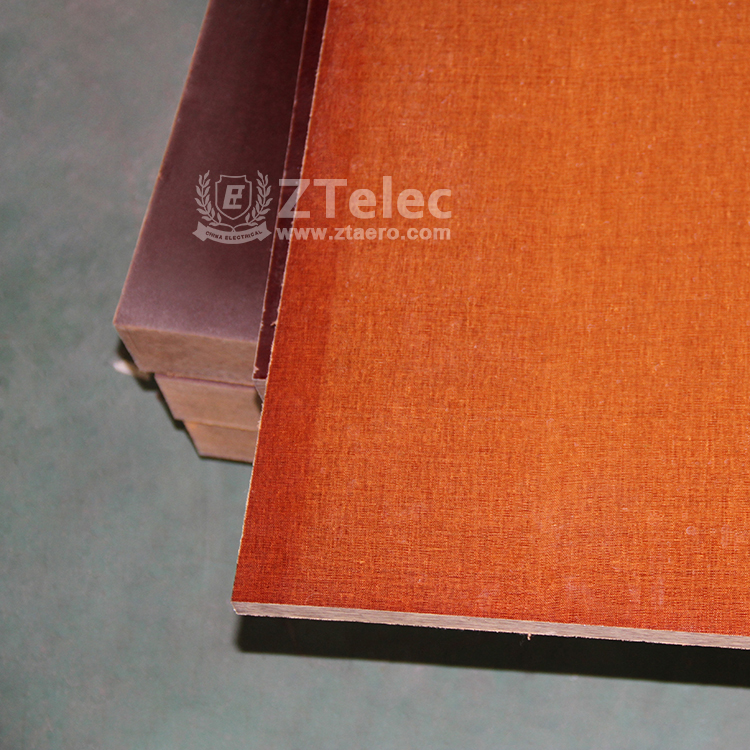

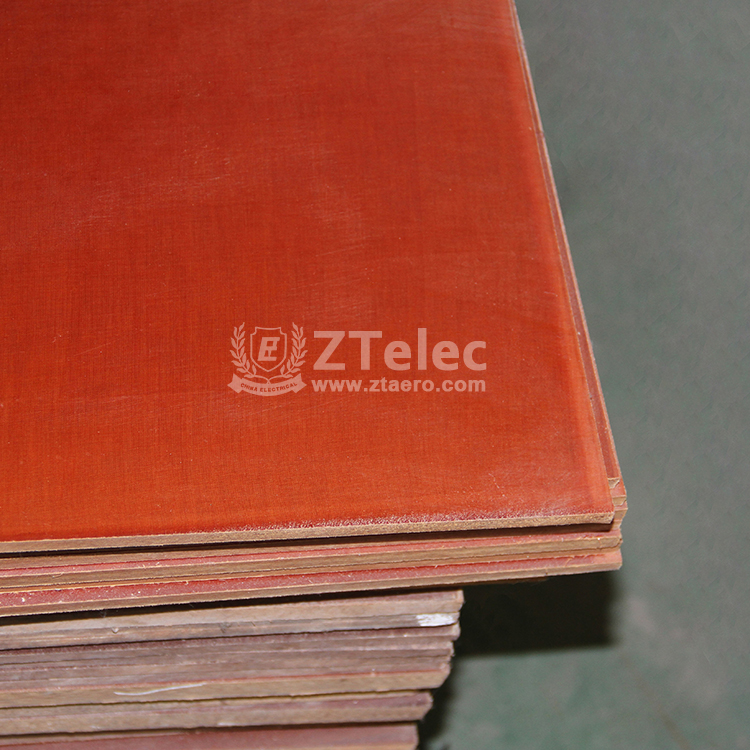

The bakelite we usually call, the chemical name is phenolic board, was the first plastic to be invented and the first plastic product to be put into industrial production. It has various colors, such as black, reddish brown and brown. It has good insulation, high temperature resistance, corrosion resistance, low water absorption, simple production process and low price.

In 1905, the American chemistry doctor Beckerland mixed phenol and formaldehyde when testing new materials. The combination of the two becomes very viscous, and solvents such as water, alcohol, and gasoline cannot be removed. Add the crushed wood chips, stir and heat before getting it down. This piece of material combined with phenol, formaldehyde and wood chips is not soft and does not break on the ground. It is sawn smoothly with a saw. After the process adjustment and processing, the electric wood board finally came out. It can manufacture electric light switches, lamp holders, telephones, instrument cases, and secondary products, making it the world’s largest thermosetting plastic.

Now the manufacturing process of the bakelite is as follows: the phenolic resin and the aldehyde compound are firstly prepared under the action of a catalyst, and then mixed with sawdust, talcum powder, curing agent, lubricant, pigment, and finally heated in the mold. Press forming cutting.

The invention of bakelite was a pioneering work in human history, and its invention also promoted the development of other plastic products. ZTELEC GROUP is a company specializing in the production and processing of composite materials. If you need electric bakelite, epoxy board, phenolic board and its processed parts, please come to our company to buy. We have the most advanced production equipment and experienced staff, and will never let you down.