How to Choose the Rubberized Polyimide Film on the Market

To form a multilayer PCB on a soft insulating substrate, the finished product must be formable rather than continuously deflectable: this multilayer flexible PCB is made of a soft insulating material. Although it is made of a soft material, it is required to have a thick conductor, or a required impedance or capacitance, to be thick between the signal layer and the ground layer due to limitations in electrical design, such as for the required conductor resistance. The insulation is isolated so that it is formed during the finished product application. The term “formable” is defined as the ability of a multilayer flexible PCB component to have the desired shape and can no longer be flexed in an application.

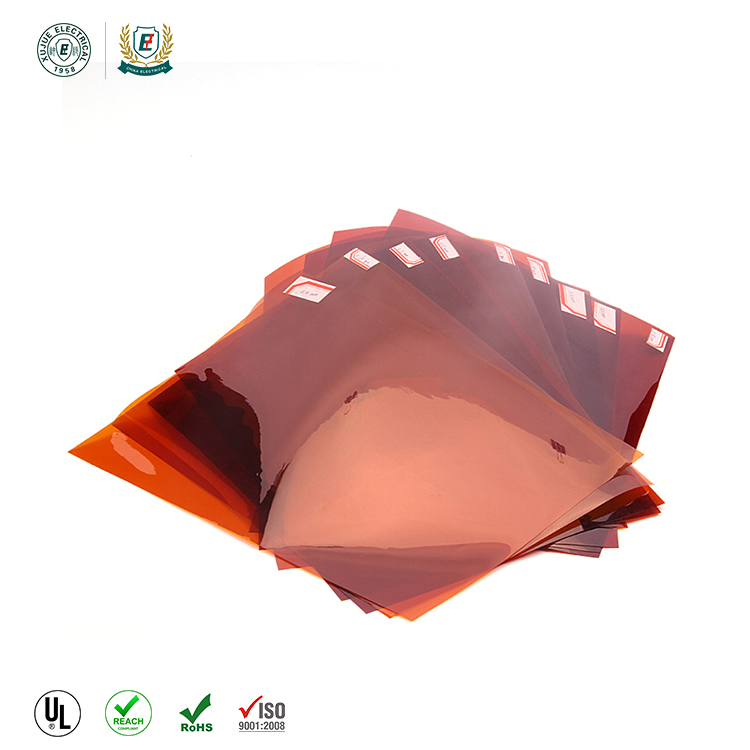

Used in the internal wiring of avionics units. At this time, the strip conductor or the three-dimensional design is required to have low conductor resistance, minimal capacitive coupling or circuit noise, and can be smoothly bent at 90° at the interconnect end. This wiring task is achieved by a multilayer flexible PCB made of polyimide film material. Because the rubberized polyimide film is resistant to high temperatures, flexibility, and good electrical and mechanical properties. In order to achieve all of the interconnections of this component section, the trace portion can be further divided into a plurality of multilayer flexible circuit components and bonded together to form a printed circuit bundle.