Insulated Crepe Paper Needs to Be Wrinkled Evenly and Trimmed Neatly

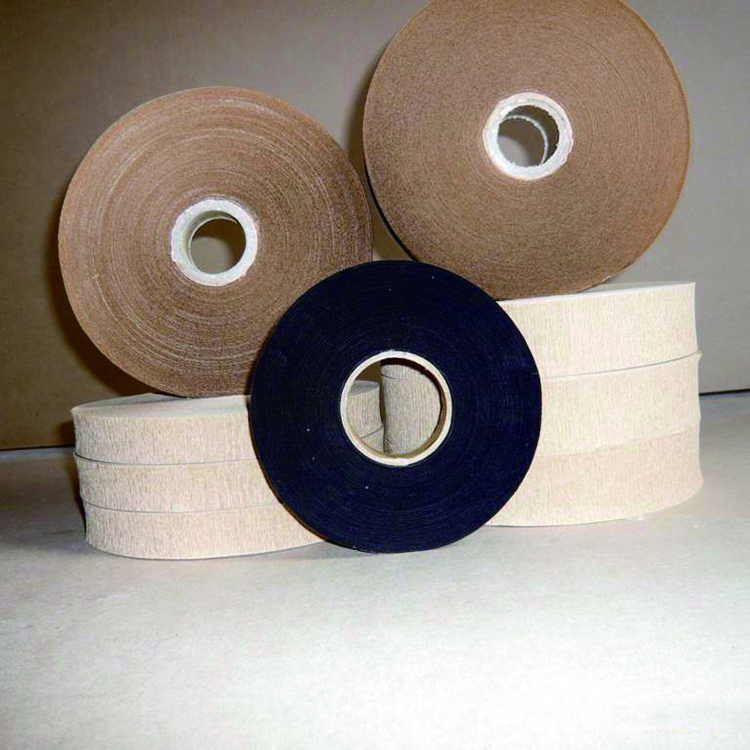

Insulated crepe paper can be combined with transformer oil to form an oil-paper insulation. The dielectric constants of the two are relatively close. It can make the electric field between them more uniform. The lead wire should be bent, and the crepe paper can be bent with the lead wire without being broken to meet the mechanical requirements. The thickness of the insulating crepe paper is 0.30 mm to 0.40 mm, and the average value is 0.35 mm. The insulating crepe paper has a width of 25 mm. 30 mm. 40 mm. 100 mm.

Insulated crepe paper is suitable for oil-immersed transformers, crepe paper for reactor and transformer insulation. Insulation crepe paper needs to be wrinkled evenly, no folding, damage, trimming should be neat, uniform thickness, insulating crepe paper should not have any impurities, pinholes, water marks and pulp. Qualified insulated crepe paper is subject to the performance standards: Q/BNJ01-2004.

Insulating crepe paper has a long history as an insulating material for electrical equipment. Before the 20th century, insulating materials were basically derived from natural materials or their products. In order to improve the water resistance and the like, a natural resin such as shellac is used for dipping with vegetable oil or asphalt. At the beginning of the 20th century, due to the development of organic synthesis and polymer chemistry, humans made the first synthetic polymer-phenolic tree tire, which is also an important invention in the field of insulating materials.

A large number of synthetic polymers and resins were greatly increased from the 1920s to the 1950s. These polymers are widely used in motors to improve the heat resistance, electrical performance and safety of the motor. However, synthetic polymers must be applied with volatile organic chemicals (solvents, thinners, etc.).