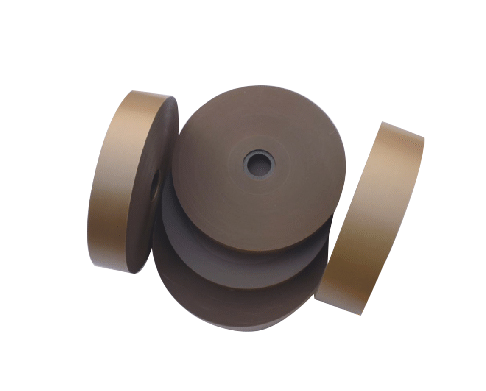

Production Process of Insulating Crepe Paper Used in Motors and Capacitors

Insulating crepe paper is pure wood pulp fiber. No additional adhesive is added. The cloth is first copied into a non-woven fabric and then pressed into cardboard. Due to its high chemical purity, the paperboard is particularly suitable for use as an insulating material in motors and capacitors, especially in oil-immersed transformers.

Due to the use of special molding and pressing procedures in its manufacturing process, high density and dimensional stability of the insulating crepe paper are ensured. Also due to its good mechanical properties, it can also be processed into fixtures and spacers for the live parts of the transformer. Under short-circuit conditions, due to good bulk elasticity, it is safe to withstand the large mechanical stresses occurring in the transformer.

Because of the mechanical strength and excellent oil leaching performance of insulating paperboard products and sheets, they have been widely used in oil-immersed power transformers and distribution transformers. Insulating crepe paper has both mechanical and electrical characteristics after immersion, and the properties of this composite are not achieved by other insulating materials.

Insulated crepe paper, also known as electric crepe paper, is made from unbleached sulphate softwood pulp. After being beaten in free form, it is not glued or filled (material), and is made by applying wrinkle on the long net paper machine. It is a paper with insulating properties and gray damage function. Insulated crepe paper is also known as: transformer crepe paper and transformer crepe paper. The paper is tough and even, with high tensile strength, folding resistance, tear strength and high

elongation.