The Processing of Paper Based Copper Plate

The prepared resin liquid is injected into the glue slot of the glue machine. The resin liquid is impregnated with fiber paper, glass fiber cloth and glass fiber paper, then the drying oven is heated under the condition of 120~180 C, and the resin is in the semi curing state (B stage resin) and the solvent is removed. This process is known as glue, and its product is called top adhesive tape (or upper adhesive tape). As an important raw material used in multi laminates manufacturing, the commodity name is called prepreg, or PP, or prepreg Mongolia junction (preimpregnatedbondingsheet).

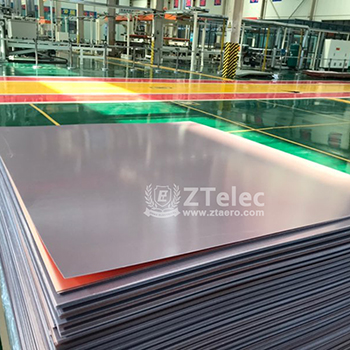

Paper glued copper clad laminate is usually used in horizontal gluing machine. The gluing process of glass cloth base copper clad laminate is usually done in vertical gluing machine. The quality control indexes of the upper adhesive paper (resincontent, RC%), resin mobility (resinflow, RF%), volatile content (volatilecontent, VC%), resin gelation time (geltime, GT), and the quality control index of the adhesive paper are also single quality and soluble resin content in addition to this. Quantity (solubleresincontent). Some manufacturers also do research and test on the quality performance of the top rubber, such as the melting Mongolia degree curve, the dioxygen gel crystallization test, the curing percentage, the proportional flow degree and so on.